Producing Mines

Altan Tsagaan Ovoo

(ATO) Gold Mine

Quick Facts

Ownership:

100%

Location:

Dornod Province, Mongolia

Status:

Operating & Expanding

Operation:

Open-Pit Mine

Commodity:

Gold and Polymetallic

The ATO Gold Mine is a multi-phase precious metals project fully owned by Steppe Gold Ltd and encompassing a single mining license over 5,492.63 hectares. Open pit mining operations commenced in 2020, initially focusing on near-surface oxide ores. As at Q2 2024, the ATO mine produced over 110,000 ounces of gold and 200,000 ounces of silver.

The ATO Mine has a significant mineral reserves which will support operations through 2036. The company is advancing the Phase 2 Expansion, expected to be completed by mid-2026, and will target an annual average production of 90,000 ounces of gold equivalent from fresh rock ores.

The ATO mine is equipped with the necessary infrastructure to sustain ongoing open-pit operations.

ATO Gold Mine is located in Tsagaan Ovoo soum, Dornod Province of Eastern Mongolia, 660 km east of the Ulaanbaatar, the capital of Mongolia, 120 km northwest of Choibalsan, the provincial capital of Dornod Province, 38 km west of Tsagaan Ovoo soum.

- Geology: ATO sits regionally within the Devonian through Late Jurassic Mongol-Okhotsk tectonic collage that has been emplaced along a transform-continental margin of the North Asian Craton (NAC). A number of Late Jurassic-early Cretaceous broad, gold-bearing mineral belts have been recognized in eastern Mongolia. ATO is located north of the Main Mongolian Lineament (MML), and midway along the NNE trending 600km long Onon base and precious-metal province that crosses eastern Mongolia. Though ATO presently represents the only well-explored gold deposit in this part of Mongolia, many minor gold occurrences have been recognized throughout the region. The geology of the ATO Project region consists of metamorphosed Devonian sedimentary rock overlain by a volcanic and sedimentary sequence of Permian age and remnant scraps of probable Jurassic volcanoclastic units, intruded by Jurassic plutons ranging from diorite to granite in composition and including rhyolitic phases mainly as dykes.

- Mineralisation: The ATO deposit is an epithermal gold and polymetallic deposit of transitional sulphides in breccia pipes in a Mesozoic continental rift zone in eastern Mongolia. It could be characterised as an intermediate sulphation system. Up to 2017 exploration focussed on three gold, silver and base metal mineralised sub-vertical pipes (Pipes 1, 2 and 4) spaced ~300 m apart on a WNW trend. Another pipe (Pipe 3) exists just west of the others but is not mineralised. Subsequently a fourth pipe-like body (Mungu) was found ~600 m to the northeast of Pipes 1, 2 and 4). The pipes have been emplaced into stratified rocks. The three pipes are elliptical in shape with the long axis oriented toward the northeast. Each have approximate surface dimensions of 300 * 150 m. The pipes taper to depth vertically. Mungu is a northeast plunging system of tall lenticular lodes. Pipes 1 and 2 are near paleo surface, epithermal (hot spring) emplacements and the upper parts of mineralized breccia pipes. Pipe 4 is slightly buried without the surface mineralisation.

- Deposit type: ATO’s mineral deposit type is that of multiple surface epithermal deposits with intermediate sulphidation (feeder) pipes below. This implies a specific shape where the top part (near or at current surface) would represent a wide thinnish roughly circular accumulation of mineralisation in country rock around an original surface ground-water-interacting hydro-thermal or fumarole vent system. Below that would be a tall root-shaped breccia pipe, flared at the top and narrowing downwards, through which the magmatic or meteoric fluids rose above a lower hot igneous body. The pipe would be vertically veined and/or brecciated.

Notes

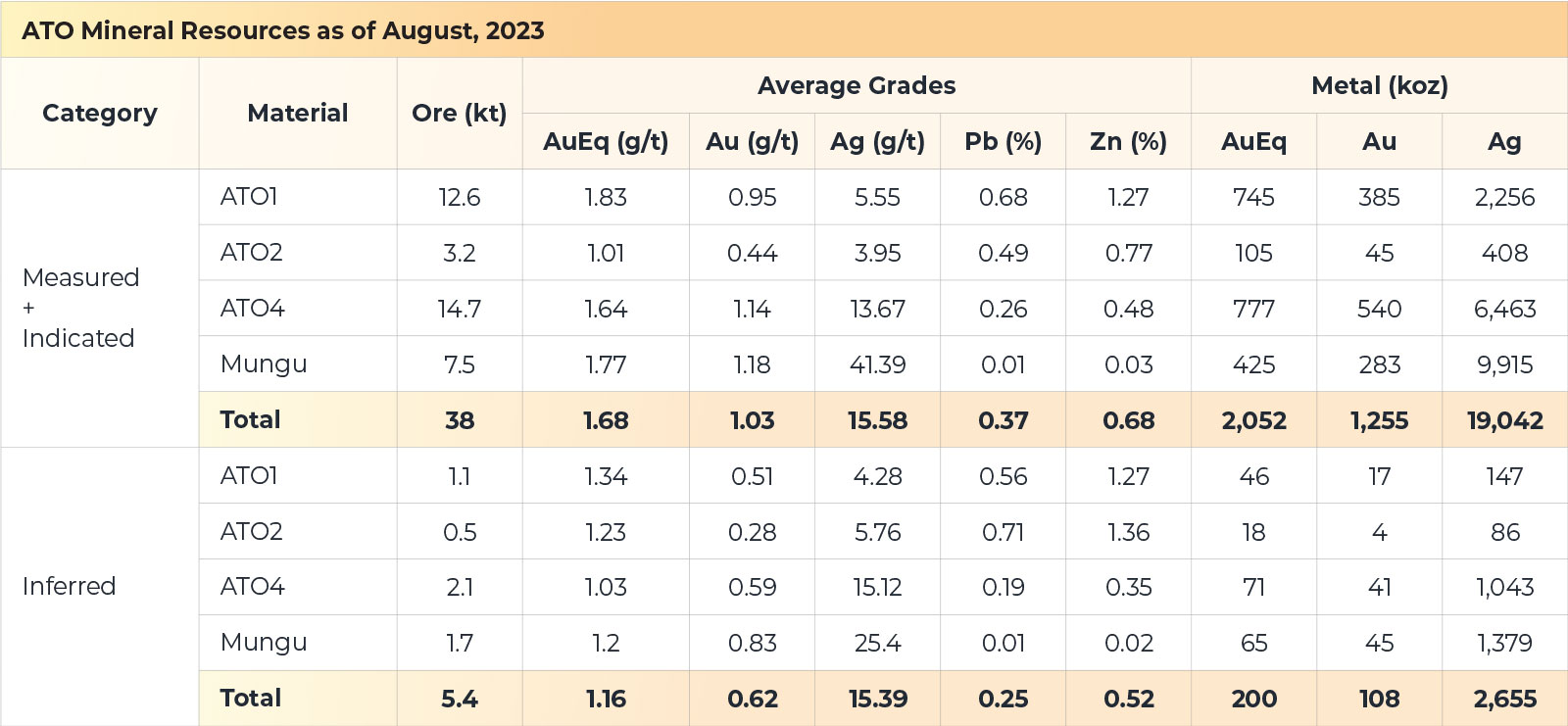

1. Mineral Reserves estimate was based on Measured and Indicated Resource Estimate by R. Rankin, QP and effective August 27 2022.

2. ATO and Mungu Mineral Reserves are effective as of August 27, 2022.

3. Mineral Reserves are included in Mineral Resources.

4. Mineral Reserves are reported in accordance with JORC and CIM and NI 43-101 guidelines.

5. Ore dilution is estimated at 3% and ore loss is 2%.

6. Contained metal estimates have not been adjusted for metallurgical recoveries.

7. The open pit mineral reserves are estimated using a cut-off grade of 0.40 g/t AuEq for oxide material and 0.43 g/t AuEq for transition and fresh material.

8. Mineral Reserves are contained within an optimised pit shell based on a gold price of $1,700 per ounce.

9. A conversion factor of 31.103477 grams per troy ounce and a conversion factor of 453.59237 grams per pound are used in the resource and reserves estimates.

10. AuEq has been calculated using the following metal prices: $1,700/oz gold, $20/oz silver, $1,970/t lead, $2,500/t zinc.

11. Totals may not match due to rounding.

12. The Mineral Reserves are stated as dry tonnes processed at the crusher.

Mining: The mining method at ATO is a conventional open pit operation with rigid body mining trucks, hydraulic excavators, and wheel loaders. The Project consists of two (2) separated mining areas: the ATO and the Mungu Pits. Only open pit mining is considered in the current mine plan; however, the Mungu deposit has additional Resources at depth which are outside the current mine plan. Therefore, there is an opportunity for the Mungu Pit to be expanded to an underground mine once the open pit reserves are depleted. All mining activities to date have occurred in the initial three ATO pits. Mining has been focused on extracting the oxide ore in these areas. No mining has commenced at Mungu.

Processing: The existing oxide ore processing facilities include the following unit operations:

Crushing and Ore Handling

- Primary Crusher: a vibrating grizzly screen and jaw crusher in open circuit producing a product P₈₀ of approximately 190 mm;

- Secondary and Tertiary Crushers: a vibrating screen and cone crushers operating in closed circuit producing a final product P₈₀ of 25 mm;

- Heap Placement: crushed ore stacked to a 3,000 t capacity stockpile.

Heap Leach Pad

- Ore Heap Leaching; and

- Barren Solution Delivery and Pregnant Solution Recovery Piping Systems.

- ADR Plant

- Carbon-in-Column (CIC) Adsorption: adsorption of solution gold onto carbon particles;

- Desorption: acid wash of carbon to remove inorganic foulants, elution of carbon to produce a gold rich solution, thermal regeneration of carbon to remove organic foulants; and

- Recovery and Refining: gold electrowinning (sludge production), filtration, drying, mercury retorting, and smelting to produce gold doré.

The Phase 2 Concentrator facilities will include the following:

- The crushed ore feeders located under the ore storage facility and conveyors to the concentrator; grinding, and classification;

- Sequential Flotation Circuits for Concentrates of Lead, Zinc and Pyrite;

- Dewatering of Concentrates of Lead, Zinc, and Pyrite; and

- Tailings Thickening, Handling, and Disposal.